Benefits of Personal Injury Prevention Training

Managing risk and preventing workplace injuries

Guaranteed results – Interactive and motivational instruction to the workforce has always delivered with significant injury reduction and cost savings.

-

ZERO INJURIES – is it possible to prevent ALL injuries?

-

IMPROVED COMMUNICATION – promoting feedback so that ALL risks are reported

-

IMPROVED CULTURE – those who ‘Dare to Care’ can make a good company great

-

REDUCED COSTS – thro’ WCB premiums and Partnership in Injury Reduction (PIR) REBATES

-

REGULATORY COMPLIANCE – addresses Musculoskeletal Disorder (MSD) reduction

-

IMPROVED RISK ASSESSMENTS – personalizing risk with a focus on body positioning

-

INTERACTIVE TRAINING – participatory 'hands-on' training

-

EVERYBODY BUYS IN – focuses on personal risk and well-being beyond work.

-

ADVANTAGES OF A CHSC – experienced, educated, independent and impartial

1. ZERO INJURIES – is it possible to prevent ALL injuries?

The short answer is YES; at personal level, at a site, on a project, it can, and has been done. On the larger scale, a journey to an injury-free workplace begins with one success at a time.

It also needs to be a combined top-down, bottom-up effort. Serious injuries affect everyone.

Be the contractor of choice with the lowest injuries, not just for your clients but also to retain your good people, build on the power of reputation, and attract others with the same goal.

The most successful personal injury prevention programs begin with management involvement and exchanges of insight. A pilot course is a popular option, championed by senior management and is the ultimate ‘walk the talk’, supporting the concepts and your company vision at roll out.

2. IMPROVED COMMUNICATION – promoting feedback so that ALL risks are reported

Has telling workers to 'Be Safe' worked?

Basic level communication for everyone is essential, because most the first identified risk in any work process is a lack of understanding. Incidents often have communication issues as an immediate cause. JSA's and FLRA all require communicative skills.

Better safety discussions gets results. “Be safe” is not enough. Using your existing tools, the aim is to improve reporting, increase interventions and a willingness to offer feedback. Giving a voice to workers, especially the long-term injury-free pros – who share their wisdom on observation platforms can be as impactful as a VP’s call to action. A safe workforce is one that reports all risks, perceived or otherwise.

3. IMPROVED CULTURE – those who ‘Dare to Care’ can make a good company great

A company culture that is admired by its peers, and most importantly, the personnel that work there, begins with an organizational structure that embraces safe work attitudes, ethics, and multiple communication channels so no-one feels left out. As the saying goes, 'They don`t care how much you know until they know how much you care’. Making it easy for workers to convey their concerns and ideas improves safety AND efficiency.

Companies that offer “engaging” programs that improve the well-being of their employees reap the benefits when the company is seen to ‘care’ especially when it transfers easily to daily life.

Employees would be well served adopting safety 24/7 particularly when 65% of incidents happen off the job.

4. REDUCED COSTS – thro’ WCB premiums & Partnership in Injury Reduction REBATES

Management of injured workers is a costly business.

Slips, trips and falls along with hand and finger injuries are among the biggest challenges that industries with manual labour activities industry face. WHO also identifies musculoskeletal injuries as a global problem.

The average cost of a claim related to slips, trips and falls was $10,411, and on average, each slip, trip and fall injury resulted in 85 days lost from work. [Nova Scotia, WCB 2010-2015]

Recent research suggests $20K - $40K including indirect costs, which include worker and equipment replacement, downtime and other expenditures.

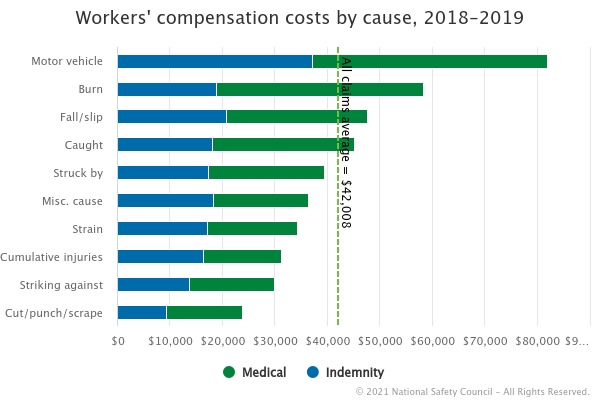

US data provided by the National Safety Council, (above), appears to be the most consistent, year over year.

Companies should always evaluate how many dollars does it take in sales to offset the cost of a single injury - possibly hundreds of thousands. Nothing incentives more that the ‘bottom line’.

Elimination of injuries reduces immediate costs and ultimately your WCB rate.

Partnership in Injury Reduction is a voluntary program that operates through the efforts of WCB, government, safety associations, etc. It can help reduce your premiums through rebates of up to 20% by maintaining a Certificate of Recognition (COR) and reducing injuries.

Consider that preventing even one injury within your company could be worth many times the cost of this training course.

5. REGULATORY COMPLIANCE – addresses Musculoskeletal Disorder (MSD) reduction

Example: Alberta’s ‘Part 14 Lifting and Handling Loads’ of the OH&S code states:

211.1(1), a worker who may be exposed to the possibility of musculoskeletal injury

is trained in specific measures to eliminate or reduce that possibility that includes,

211.1(2), identification of the early signs and symptoms of MSD’s and,

210(1), assessing manual handling hazards.

Many companies unknowingly fail to comply with these or other jurisdiction’s requirements.

6. IMPROVED RISK ASSESSMENTS – personalizing risk with an emphasis on body positioning

More specific instructions on the completion of risk assessments with an emphasis on body positioning.

Assessment models focus on the person first. Next, is interaction with equipment, tools and/or materials. Seldom are they specific enough that the information provides body positioning advice, beyond procedural or manufacturer recommendations.

PIP training emphasizes personal control methods which improves safe positioning of the individual.

Techniques learned maximize muscle strength, improve balance and limit strain.

7. INTERACTIVE TRAINING – participatory 'hands-on' training.

Motivate, tell & show, test and check is ten times more effective than lecture-based training.

Techniques that can prevent or limit the risk of injury due to stepping, handling are demonstrated and practiced.

The exercises involve everyone moving their bodies into positions of balance, stability and strength.

Personal Injury Prevention training is transformational and includes ‘at home’ examples that encourages sharing and retention.

8. EVERYBODY BUYS IN – focuses on personal risk and worker well-being beyond work.

Early PIP sessions for senior managers often yields the best results. Promotion, through vocal and visible commitment contributes significantly to the successfulness of the program.

"Highly interactive, engaging and FUN!" Participants see the training they receive as a ‘life skill’ and say the learned techniques go home with them. Satisfies the “What’s in it for me”.

Workers take what they have learned, and put it into practice, reflected in the comments received including a few, below from the course participants:

“…the most extensive, in depth training I have ever received.”, carpenter

“A lot of the content was a big eye-opener”, loader operator

“Never heard of most things – nice change from same old safety routine”

“Good Information I haven’t heard before……”, production operator

“Of the hundred guys that took your course last year, none of them have had an injury”, Mgmt.

9. ADVANTAGES TO HAVING A CHSC CONSULTANT ON YOUR TEAM – experienced, independant and impartial.

Ian McCabe, CHSC, Certified Health and Safety Consultant, has been practicing OHS for more than 15 years and specialises in Injury Prevention programs. His strong communicative skills combined with years of operations management experience provides effective training and improved HSE performance.

Also a CHSC offers the following advantages:

• Mandatory Continuous Professional Growth

• Ethical Code of Conduct and Professional Insurance

• Independent and Impartial.